Tungsten copper spot welding needle has many advantages, such as small in volume, excellent electrical and thermal conductivity, high welding stability, good anti-adhesion and no bombing fire, etc., in the micro-battery spot welding field has broad application prospects.

Types

|

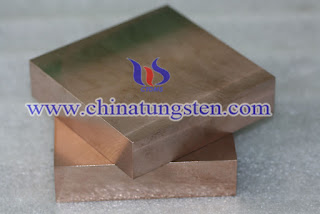

| Tungsten Copper Spot Welding Needle Picture |

According to the differences of the shapes and structures, tungsten copper spot welding needle can be specifically divided into single head center solder pins, solder pins single eccentric head, double-headed center solder pin, eccentric stud welding spot welding needle, insert needle and so on. Common micro spot welding batteries includes laptop battery, cell phone battery, walkie-talkie battery, difital camera battery, button battery, lithium battery, nickel hydride nikel-cadmium battery, etc., the specific selection should be considered with the structure and the properties of the products.

Notice

1. Before spot welding, it should be ensured that the welding needle and the surface welded at the same level;

2. Before spot welding, it should be checked if the welding needle has been oxided of burned and use sandpaper or a sanding belt to smooth surface until the surface is smooth and no oxides;

3. The same spot welding joints can not be welded twice, and to ensure that the positive and negative electrodes have four effective solder joints;

4. There is no bombing fire and over-burnt phenomenon.

Any feedback or inquiry of tungsten copper alloy products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595

Fax.: +86 592 512 9797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.